Urban Disaster Risk Assessment in Newly located Tannery based Industrial Areas in Bangladesh- Juniper Publishers

Juniper Publishers- Open Access Journal of Annals of Reviews & Research

Urban Disaster Risk Assessment in Newly located Tannery based Industrial Areas in Bangladesh- Juniper Publishers

Authored by ABM Nurullah

Abstract

Tannery industry is the mentionable second largest revenue sector in Bangladesh. The main purpose of the study is to assess the health and environmental risk generated from the production activities of the tannery industry. A newly formed leather industry city in the Hemayetpur area of Bangladesh have been selected for this study. We have followed the process of risk assessment along with key informant interview (KII) and focused group discussion (FGD) among workers and administrative officials. The study retains that the workers are in the higher level of health risk and the industries are producing an unbearable environmental hazard in the area. The study suggests that a strong initiative should be taken by the government authority to monitor the tannery industry especially new areas to control environmental pollution and various kinds of health hazards.

Keywords: Disaster; Urban area; Tannery industry; Environmental pollution; Bangladesh

JEL Classification: P23, Q52, Q54.

Abbreviations: FGD: Focused Group Discussion; KII: Key Informant Interview; ETP: Effluent Treatment Plant; BELA: Bangladesh Environment Lawyers Association

Introduction

Leather sector is an important sector in Bangladesh which has potential growth and foreign investment attracting capacity [1]. The tannery products of Bangladesh have an international reputation due to its nice fibred skin which helps to produce ovine, bovine and caprine [2]. Bangladesh can produce 180 million square feet leather in every year which is produced from almost 113 tanneries [3]. The High Court already ordered the closure of all tanneries in Dhaka city immediately following a writ petition filed by the Bangladesh Environment Lawyers Association or BELA. Leather businesses challenged the order in the Appellate Division but failed to secure a verdict in their favour. Following the appeals court’s order, they then moved the High Court, seeking permission to run operations until the Eid-Ul-Azha, to be observed in the first week of September. Almost more than 60 percent tannery industries have been relocated in the newly formed leather industry city in the Hemayetpur area in Bangladesh [4]. The main goal of relocating this industry was to make rivers safe from pollutions. But the goal is not being attained in the newly formed industrial area [5]. As Central effluent treatment plant has not been built in the area, the same hazard is going to attain from the area. They are now discharging non-treated affluent in the near Dhaleshawri river [6]. They are polluting river water. Thus, our study sought to understand the pattern of health risk among industrial workers and to assess the environmental hazards produced by the industry. The leather is the basis of one of the oldest industries in Bangladesh and plays a significant role in the national economy with a good reputation worldwide [7]. Since tannery industry is based on agriculture sector and processed by indigenous raw ingredients so it has potential to export and earn foreign currency in future [3]. As a finished product, tannery of Bangladesh is familiar in global market for its fiber, texture and quality [8]. About 220 tannery units are now working in Bangladesh Kabir et al, 2017 but, in fact, only 113 tanneries are in effective operation, out of these 20 units are reported to be fairly large (7 units very large), around 45 units are considered of medium size and around 48 units are considered small groups [7]. 105 of the tanneries were positioned arbitrarily in the Hazaribagh area in Dhaka where 84 per cent of the total supply of hides and skins are processed in a highly congested area of only 29 hectares of land [10]. High Court ordered the closure of all tanneries in Dhaka city immediately following a writ petition filed by the Bangladesh Environment Lawyers Association or BELA. Leather businesses challenged the order in the Appellate Division but failed to secure a verdict in their favour. Following the appeals court’s order, they then moved the High Court, seeking permission to run operations until the Eid-Ul-Azha, to be observed in the first week of September [11].

Almost more than 60 percent of tannery industries have been relocated in the newly formed leather industry city in the Hemayetpur area of a saver. The industries are producing health hazard among the workers and inhabitants and the industries are also producing an environmental hazard [12,13]. There are many studies on different issues of leather industries in the Hazaribagh area. Until there are no such types of studies on Hemayetpur tannery industrial area. Thus, here we tried to assess the risk of health hazard among workers in tannery industries and environmental hazards produced in the area. The study attempted to assess the health and environmental risk generated from the production activities of the tannery industry.

Methodology

Researcher team visited leather industry city located in Hemayetpur, saver of Dhaka in Bangladesh. The site has been newly constructed for tannery industry. This site is located on the shore of Dhaleshwri River. To acquire the knowledge about the health risk of workers in tannery industry, Researcher team interviewed 52 workers from apex tannery and R.K tannery and interviewed two administrative officers from RK tannery [14]. We also conducted two FGDs consisting 12 respondents in each from Apex tannery company and RK tannery company.

Some important points were addressed to get the actual content of the survey. As following, five steps of Urban Community Risk Assessment conducted for addressing the research gap like

a. Scoping the target area was done by formation of Ward DMC/Ward level working group/committee, consensus building with CC/Ward DM, facilitator team formation & training, distribution of Roles and Responsibilities and orientation, and primary and Secondary data collection,

b. Risk Assessment was done by transect walk and calendar, drawing Hazard Map /RRM, assessing Vulnerability [13], focused group discussion (FGD), household and institutional level vulnerability survey, mapping, validation of the data and information, and risk Statement and Identification of Risk Reduction options,

c. Risk reduction action plan was done by developing risk reduction action plan, and vetting from the expert group,

d. Vetting or impact analysis was done by using some parameters like political/social, technical/ financial, environmental and sustainability and

e. Report writing was done after consensual analysis [15].

Results and Discussion

Health risk among workers

During the interview with workers and administrative officials, we identified the following types of health hazards in the Leather industrial area.

Accidental hazards

Slips, trips and falls on the level, especially on wet, slippery or cluttered floors, while moving heavy loads such as containers of chemicals, bundles of hides, skin, leather, etc. Falls into unguarded tanning vats and pits [16]. Electric shocks caused by contract with defective and inadequate electric installations. Blows and crushing injuries caused by unguarded rotating or moving parts of machinery. Burns caused by contact with hot surfaces or splashes of hot solutions [17]. Cuts and stabs are usually happened by the working tools which is used by the workers in tannery factory. Sometimes flying particles cause the eye injuries which is generated from rotary buffing machines.

Accidental hazards

Slips, trips and falls on the level, especially on wet, slippery or cluttered floors, while moving heavy loads such as containers of chemicals, bundles of hides, skin, leather, etc. Falls into unguarded tanning vats and pits [16]. Electric shocks caused by contract with defective and inadequate electric installations. Blows and crushing injuries caused by unguarded rotating or moving parts of machinery. Burns caused by contact with hot surfaces or splashes of hot solutions [17]. Cuts and stabs are usually happened by the working tools which is used by the workers in tannery factory. Sometimes flying particles cause the eye injuries which is generated from rotary buffing machines.

Physical hazards

Exposure to high noise levels from mechanical equipment (particularly drums, reverse settling machines, through-feed staking machines). Callosities on hands caused by continuous strenuous work with hand tools [6]. Various physical hazards are usually caused by the flying particles and polluted environment [18] (Figure 1).

Chemical hazard

Skin rashes and dermatitis as a result of exposure to cleaners, solvents, disinfectants, pesticides, leather-processing chemicals, etc (Figure 2). Allergies-contact and systematic - caused by many of the chemicals used in tanneries [19].

Biological hazards

Raw hides and skins may be contaminated with a variety of bacteria, molds, yeasts, etc., and various diseases (e.g., anthrax, leptospirosis, tetanus, Q- fever, brucellosis, etc.) may be transmitted to tanners (Figure 3) also the large quantities of dust produced in buffing operations would normally be contaminated with disease-bearing microorganisms, putrefaction products, etc [20]. Ergonomic, psychosocial and organizational factors [21]. Physical overexertion is generally a cause of acute musculoskeletal injuries due to bundles of hides, skins and leather [22]. Lower back pain due to prolonged working in a standing or semi-bending posture. Lower back pain due to prolonged working in a standing or semi-bending posture. In most of the tannery factories, there is no proper ventilation and air conditioning. As a result, workers are suffering heat stress especially in the summer season [17].

Environmental Hazard Produced from Tannery Industries

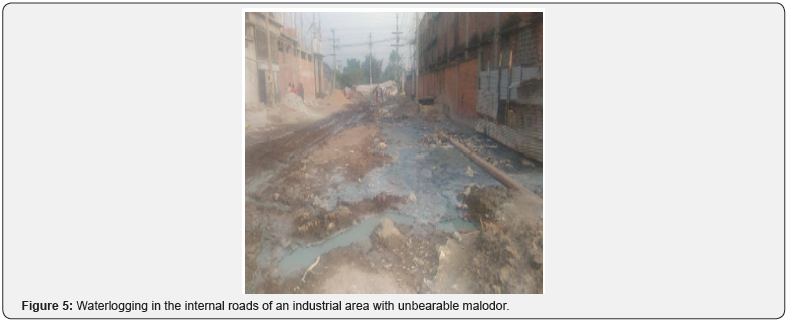

Wastewater logging in the internal roads

Due to the lack of adequate sewerage system, the wastewater of the tannery industry become logged in the internal roads of the industrial city [10]. As a result, malodor spread in the area (Figure 4 & 5). Smart city governance is necessary to control the worst situation and providing comfortable city life [23]. Water logging condition is also a barrier for smooth transportation. Most of the city dwellers living in the study areas are tannery workers, garments workers or transportation labourer. The water logging condition not only a barrier for transportation but also an agent of various diseases [21].

Unavailability of Effluent Treatment Plant (ETP)

During the interview with administrative officers of RK tannery, an officer said that there is no effluent treatment plant in any of the industries in the area [12]. There is no central effluent treatment plant in the area, as a result, all the effluent of the industry discharged into the near Dhawlwshari river [24]. The effluent is spread over the road and footpath which causes serious health hazards (Figure 6 & 7).

Discharge of non-treated tannery effluents in Dhaleshawri river

As there is no treatment plant, all the tannery effluents are being discharged in the nearing Dhaleshawri river [25]. As a result, the water of the river has been polluted with malodor (Figure 8 & 9). During the informal discussion with a local community of people, a 61 years old man said that “They destroyed our river. Some days ago we bathed here, we bathed cattle here, catches fish in the river. But now we cannot catch fish, bath here or wash anything here.” Another old man grazing near the river said that “Today, I came here with my cattle to bath them, but after seeing the quality of water I did not do it”. Respondents also said that “we cannot catch fishes from the river now. Fishes are dying every day. Though someone catches fish from the rivers they cannot eat the fish because of the bad odour of the fishes”.

Conclusion

The result of the study reveals that there are many types of health risk in the tannery industry. The workers are very much vulnerable to accident hazards, physical hazards, chemical hazards, biological hazards who work in the tannery industries. These industries are producing environmental risks. Wastewater logging in the internal roads with unbearable malodor is the salient feature of the area. As there is no effluent treatment plant centrally or individually non-treated effluents are being discharged into Dhawleshari River every day. As a result, the water is being polluted and the biodiversity of the area become hampered. The study suggests that a strong initiative should be taken by the government authority to monitor the tannery industry especially new areas to control environmental pollution and various kinds of health hazards.

To know more about Juniper Publishers please click on: https://juniperpublishers.com/aboutus.php

For more articles in Open

Access Journal of Reviews & Research please click on:

https://juniperpublishers.com/arr/index.php

Comments

Post a Comment